Latest News

NextOre welcomes Pfeiffer as strategic investor, partner for next-gen minerals processing

Australian mining technology business NextOre Ltd (NextOre or the Company) is pleased to announce that it has entered into a Strategic Cooperation Agreement and a Share Subscription Agreement with Gebr. Pfeiffer (Pfeiffer), a leading German comminution technology company.

NextOre Ltd closes $5.2m Series B growth capital raising

Sydney-based mining technology business, NextOre Ltd (NextOre), founded by CSIRO and industry partners, has completed a Series B growth funding round of $5.2m. The Series B funding round was cornerstoned by existing shareholder RFC Ambrian Funds Management through its newly formed QCM Fund.

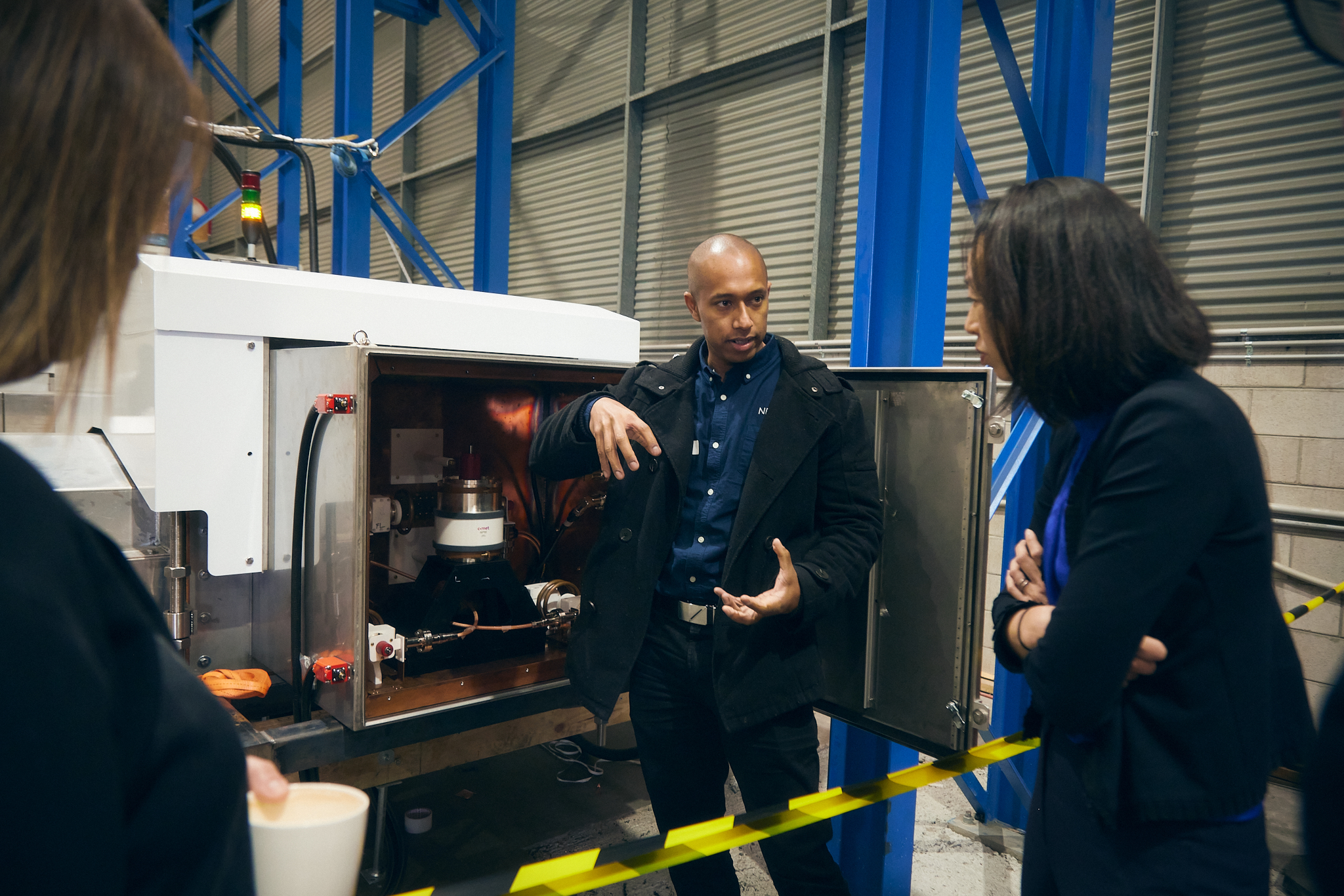

World first magnetic resonance truck analyser dispatched

NextOre has completed assembly and factory testing of a world first MR truck analyser. The unit, measuring 7m in diameter and designed to be suspended 10 meters over 180-tonne trucks, has been sold to its first customer and will be dispatched to a large copper mine overseas in March. The analyser will be used to detect copper as chalcopyrite.

NextOre Awarded Mines and Money Technology Company of the Year 2022

NextOre has completed assembly and factory testing of a world first MR truck analyser. The unit, measuring 7m in diameter and designed to be suspended 10 meters over 180-tonne trucks, has been sold to its first customer and will be dispatched to a large copper mine overseas in March. The analyser will be used to detect copper as chalcopyrite.

NextOre’s mobile bulk sorter now available for hire

NextOre has revealed its newest product during the RFC Ambrian Copper to 2030 webinar. It has been designed to suit small mines and those seeking to monetise historical dumps, or to provide a rapid test method for bulk sorting to support a potentially much larger bulk sorting plant.

NextOre Wins Australian Technology Competition 2020

Commercialisation of Australian science for national benefit has today been recognised with Australia’s national science agency, CSIRO, sharing a win with partner NextOre in the best licencing deal category of the Knowledge Commercialisation Awards 2021.

Magnetite Mines Enters Into Agreement With NextOre

Commercialisation of Australian science for national benefit has today been recognised with Australia’s national science agency, CSIRO, sharing a win with partner NextOre in the best licencing deal category of the Knowledge Commercialisation Awards 2021.